- HOME

- Products

- Panel furniture production line

- CNC six-sided drilling machining center

Six-sided CNC drilling machining center

Functional characteristics

The CNC six-sided drill is an efficient equipment dedicated to solving the void process in the production of panel furniture.

No need to reprint, after importing the processing data at one time, scan the code to complete the processing.

The upper and lower spindles can simultaneously process front and back symmetrical slots.

Yaskawa bus absolute value servo. Ensure positioning speed and response time.

Yintai rail. Ensure accuracy and give full play to servo performance.

Data docking, ban/xml/dxf/mpr, etc.

Taiwan Puten row drill. Sidetracking roller, vertical pressing plate, lower support plate, three ways to ensure the fixing of the plate.

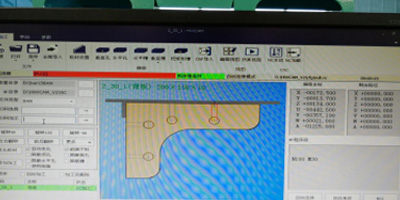

Simple operation and detailed display

Perfect management

Perfect 5S site management, strict quality management system, and excellent high-skilled personnel ensure the quality of all machines.

Dedicated control system

Yiming special control system, the system and CAM software are developed by one company, the user-made operation interface is easy to learn and use. A variety of data formats can be docked, such as BAN, DXF, XML, MPR, BD, etc., and mainstream software in the market can be docked.

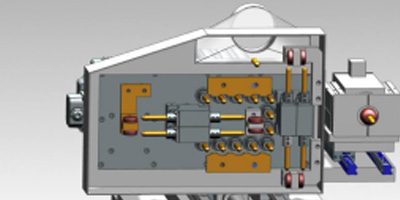

Control cabinet

The important electrical components in the control cabinet are all Siemens appliances; the main circuit is equipped with a filter to eliminate interference and ensure the stability of the control system.

Special row drill for six-sided punching series

Special row drills for six-sided punching series, adding a variety of pressure plate pressure wheels to ensure the accuracy of the punching chute.

German Heiden Servo

German Heiden servo is equipped with Xinbao reducer, with large torque, ensuring the processing speed and stability of the equipment. The Z-axis adopts a brake motor, which can protect the machine head from slipping down after the power is off

Intime 30 square rail

The specifications are relatively large, the contact surface is large, and the load-bearing capacity is strong. The mounting surface of the guide rail is all milled flat on a large milling machine, and CNC punched, with high installation accuracy. The Z-axis and W-axis Taiwan TBI screw rods are not deformed for long distances, ensuring fine transmission.

Adopt a new type of drag chain

The use of a new type of drag chain, divided into four compartments, separates the signal line and the power line according to the specifications, better defends against signal interference, and also prevents the cable from being twisted together during the working process. The cable adopts high-flexibility shielded wire, which has a longer service life

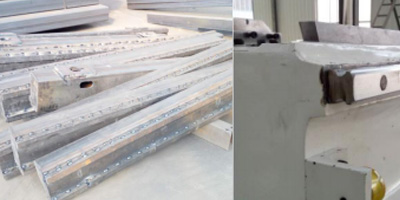

bed frame

It adopts square steel welding and tempering treatment to eliminate welding stress and ensure that it will not be deformed after many years of use. The bed stiffeners are denser, which increases the strength of the bed and ensures that the bottom plate is not deformed.

bed frame

The bed must undergo vibration aging and tempering treatment, and the installation surface of the large CNC machining center is milled

Rail mounting surface

The mounting surface of the guide rail is welded with steel strips, and the bolt confinement depth is increased when the guide rail is installed, which increases the load-bearing capacity and ensures the rigidity of the equipment

Product video introduction

CNC six-sided drilling machining center

Horizontal six-sided drilling machining center, beam through structure, six-sided drilling operation is completed at one time.

双夹钳,根据板材长度自动调节夹持位置。

Vertical+horizontal+saw blade row drilling with spindle can realize diversified processing.

Equipment technical parameters

model | YM-V1-12 | YM-VI-12S |

Maximum sheet size (width) | 1200 | |

Min sheet width | 30 | |

Minimum sheet length | 200 | |

Fastest processing speed | X/U130、YN70、ZNW30 | X/U130、YN70、ZW30、O/R709 |

Number of motion axes | 7 | 9 |

Number of drill packs | Up 1 down 1 | Up 2, down 1 |

Control system and CAM | Hyde League | |

Drive System | Absolute value of HIDM bus | |

Number of upper horizontal drill shafts | Left and right 2, front and rear 2 (HQD) | |

Number of upper vertical drilling spindles | 12( HQD ) | |

Number of vertical drill shafts | 6( HQD ) | |

Number of upper spindles | 1 ( HQD3.5KW ) | |

Number of lower spindles | 1 ( HQD3.5KW ) | |

working pressure | 0.6-0.8Mpa | |

Total power | 16KW | 21KW |

Operating Voltage | AC380V/3PH/50Hz | |

Dust suction port size | φ 150mm | |

Dimensions (length x width x height mm) | 5000x 2580 x 2000mm | 5000×28 10x2000mm |

Cut sample