- HOME

- Products

- All aluminum home CNC equipment

- Automatic edge banding machine

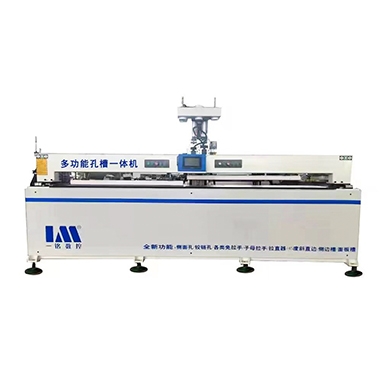

Automatic edge banding machine

Functional characteristics

YM-828SL-PUR fully automatic edge banding machine, with a maximum speed of up to 30m/min. This model is fully functional, with a stable and powerful system, intelligent operation control, and high-speed and efficient production, suitable for mass production of aluminum honeycomb panels

用高品质材料及品牌配置,能够适应于高低温气候及其他恶劣环境中进行生产运作,具备生产稳定、省维修、耐用性等特点。

Main functions: pre milling - six wheel pressing and pasting - gluing and pasting 1 (PUR glue pot+PUR automatic glue injection machine) - gluing and pasting 2- double guide rail alignment - rough trimming - fine trimming - four blade tracking - scraping edge 1- scraping edge 2- flat scraping - polishing 1- polishing

Scope of use

The fully automatic edge banding machine is suitable for edge banding processing of aluminum honeycomb board, medium density fiberboard, blockboard, solid wood board, particle board, polymer door board, plywood and other boards. It can have functions such as conveying, gluing, pressing, trimming, rough trimming, fine trimming, profiling tracking, scraping, polishing, etc. at once. Its edge banding effect is delicate, smooth, and has a good hand feel, and the sealing line is straight and smooth. This device is stable, reliable, durable, and reasonably priced, especially suitable for large and medium-sized furniture factories, as well as manufacturers of panel furniture such as cabinets and wardrobes. Its characteristics are automation, high efficiency, high precision, and aesthetics, and it has been widely used in domestic panel furniture production enterprises.

Equipment technical parameters

model | Model | YM-828SL-PUR |

Machine size

| Overall Size(L X W X H

| 10500*970*1800mm

|

working pressure

| Working Pressure

| 0.6Mpa

|

Total power

| Total power

| 25KW

|

Feed rate

| Feed speed

| 22-26m/min

|

Electric lift

| Electric lifting

| 0.37KW

|

Sheet thickness

| Panel Thickness

| 10-60mm

|

Sheet length

| Sheet length

| >120mm

|

Sheet width

| Panel Width

| ~60mm

|

Edge band thickness

| Edge thickness

| 0.4-3mm |

configuration list

Serial number | Configuration model

| brand

| Brand logo

|

1 | 输送电机

| Tengwan/Taibang

|

|

2 | Rubber pot high-temperature bearing

| Germany/SWC

|

|

3 | Equal head/other cylinders

| Yadeke/WSM

|

|

4 | Tracking cylinder

| AirTAC

|

|

5 | proximity switch

| Knox

|

|

6 | PLC

| DELTA

|

|

7 | Frequency converter

| Huichuan/Taiwan Delta

|

|

8 | touch screen

| DELTA

|

|

9 | 接触器

| Schneider, France

|

|

10 | solenoid valve

| Schneider, France

|

|

11 | Rubber pot sealing ring

| Taiwan/SOG

|

|

12 | water separator

| EASUN

|

|

13 | 高速电机

| German UFC/Tianyi

|

|

14 | 温控表

| AUTONICS

|

|

15 | 行程开关

| Kaikun, South Korea

|

Equipment detail photos

Image display | function | Detailed description |

| Touchscreen: | 15 inch industrial high-definition touch screen, with a large screen for easy clicking and larger buttons. |

| Pre milling | Diamond pre milling cutter is used to mill away the ripple marks and excess burrs on the spiral edge trimmer of the wooden board, so as to The edge of the board is more closely attached to the edge banding, with a stronger and more aesthetically pleasing adhesion. The pre milling seat with pneumatic control is more precise and convenient to operate. |

| PUR glue pot Six wheel adhesive tape wheel | No need to clean PUR glue pot, no glue stored, directly inject glue onto the glue coating shaft, no need to clean, eliminating the step of cleaning PUR, and improving production efficiency. Pur special adhesive is waterproof, moisture-proof, and high-temperature resistant, making it the first choice for high-end edge sealing such as balcony doors, bathroom cabinets, etc. After edge sealing, it is firmly bonded and never peels off. |

| PUR automatic glue injection machine | Automatic constant temperature, automatic glue injection, and automatic control of glue. Environmentally friendly PUR adhesive, waterproof, moisture-proof, and high-temperature resistant, suitable for edge sealing of products in various special environments such as humidity and high temperature. |

| EVA glue pot Six wheel adhesive tape wheel | The traditional bottom glue pot paired with a six wheel pressure stick double glue pot can take turns using different colors of glue, eliminating the need for frequent cleaning of the glue pot and improving efficiency. Six rounds of pressing and pasting make the edge banding tape adhere to the surface of the board, and the rubber wheel tape is elastic, resulting in better adhesion. |

| Double guide rail end cutting | Double guide rails with head and tail aligned, faster and more stable speed, eliminating board collisions. |

| Rough Fine trim | Adjustment method: The five-star handle with a digital meter adjusts the trimming thickness of the rough trimming knife, which is intuitive, simple, and easy to learn. The six blade alloy flat knife removes excess edges |

| Fine trim | Six bladed R-blade trims excess edge banding to form rounded corners, resulting in more aesthetically pleasing trimming |

| Four blade tracking edge trimming Coraping trim | Trim the four corners after edge banding into small curves for a smoother and less irritating effect. Four blade tracking refines the traditional two head tracking action into four actions, which are independently controlled by four motors, increasing the speed by 50% and making the actions more reasonable without damaging the board. |

| Scraping * 2 groups Scraping * 2 | Two sets of pneumatic controlled scrapers do not require separate calibration, and the screen is in place with just one click. Scratch the fine lines on the edge banding with a superhard alloy R-knife to make it smooth. |

| Broken wire | The anti-collision wire breakage mechanism pulls the edge sealing thread that has been scraped off, preventing the scraped thread from running to the polishing motor and conveying motor behind. |

| Scratching | Scrape off the edge banding above the board surface and excess glue on the board with an alloy flat knife |

| 2 sets of reciprocating polishing Buffing * 2 | 布轮快速对封边条边缘进行抛光打磨,选择不同抛光轮对应深浅不同胶水,防止脏版。气动往复式抛光,抛光电机气动进出,抛光轮使用面积更大,抛光效果更好 |

| Centralized Lubrication System | Automatic timing oil injection and maintenance, multi-channel oil pipes are connected to each key moving part, all-round lubrication, reduce machine wear and extend machine service life. |

| 清洗装置(前隔离后清 洗) | Spray isolation liquid on the board surface to prevent glue from overflowing. Cleaning residual glue on board components, more aesthetically pleasing, adjustable nozzle water volume, convenient to use |

| Plate clamping device | Narrow panels will not shake or shift due to external forces during pressing and aligning, resulting in more stable operation |

| Narrow board auxiliary guiding ruler | When sealing the edges and aligning the ends of narrow panels, fix the panels to prevent tilting. |

| Conveyor (optional accessory) | Narrow panel feeders with high safety and efficiency |

| Edge sealing effect | The edge banding effect is smooth and beautiful, with good wrapping and perfect chamfering. |

service

1. Equipment installation and debugging

(1) After the equipment arrived, the Yiming CNC technical engineer arrived at the user's site on the same day for installation and debugging training.

(2) Please prepare the work before the engineer arrives at the site. For example: unloading equipment, equipment site, power supply, computer, power strip, leakage protector, please actively cooperate with users. After equipment debugging, please request user acceptance.

2. Training

(1) Free pre-sales training for customers.

(2) The trainees must have a certain level of relevant education and knowledge. The supplier will provide training to customers in programming, operation, processing, and daily maintenance. The trainees must be fixed and study diligently.

(3) The supplier's technical engineers conduct periodic follow-up visits to customers and engage in technical exchanges on machine operation and product processing. Users can consult any questions at any time via phone or email.

3. After sales service

(1) Free maintenance of the machine during the warranty period, and equipment maintenance beyond the warranty period will be priced clearly.

(2) The warranty period provides customers with two free maintenance services.

(3) General maintenance work is carried out on-site, and the repair response time does not exceed 24 hours.

(4) The whole machine comes with a one-year warranty.