- HOME

- Products

- All aluminum home CNC equipment

- All aluminum plate processing center

All aluminum plate machining center scheme

Functional characteristics

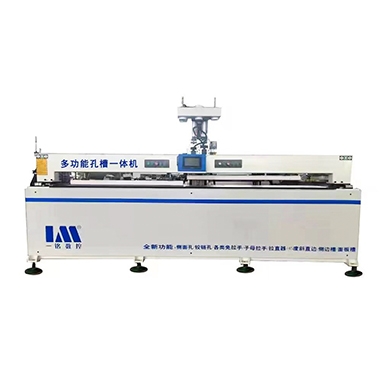

The YM-1360 Double Saw Blade Double Pressure Roller Straight Line Tool Change Processing Center is an efficient machine specialized in cutting, punching, grooving, and shaping cabinet door panels for all aluminum furniture. It completely replaces traditional push table saws and electronic cutting saws, eliminating the dependence on manual labor in traditional cutting modes. Vertical holes are also completed simultaneously while cutting, and intelligent production is truly achieved by combining with specialized design and disassembly software. Save labor, materials, and time!

◆ High quality, automatic design, automatic typesetting, automatic program loading, no manual intervention, minimizing error rates, ensuring order quality

Fast speed and high efficiency, with an idle speed of up to 70 meters per minute. True annealing aging bed, rack and pinion transmission mode, stable transmission, ensuring long-term high-speed operation without deformation and shaking

◆ Adopting the Italian Ouli 9KW air-cooled high-power automatic tool changing spindle, it works stably for a long time, and the driving system adopts the Taiwan Maixin servo 850W motor.

◆The tabletop is an internationally leading high-strength, vacuum adsorption tabletop with high adsorption force, which can strongly adsorb materials of different areas.

◆ Intelligent protection of workbench: to prevent possible damage to the workbench caused by misoperation or software errors. Intelligent processing boundary protection to prevent mechanical collisions caused by design layout exceeding the processing width

◆台湾精科控制系统,自动完成多重层面 3D 加工。能够进行快速、平滑的三维立体加工,雕刻或切割。可实现脱机操作。

Equipment technical parameters

name | Model (YM-1360 Double Saw Blade Processing Center) | |

1 | Effective stroke | Effective travel of X-axis 1300mm, Y-1 axis 3000mm, Y2: 3000mm, Z-axis 200mm |

2 | Bed structure | Six legs, a square tube with a thickness of 7.75, a stretched frame square tube with a thickness of 200 * 250, a stretched support of 100 square tubes, and a horizontal and vertical support full of the tabletop with a spacing of 40 centimeters. The steel strip on the guide rail surface and rack processing surface is 20 millimeters thick, and the overall weight increases by more than 500 kilograms. The stability and speed are matched |

3 | Processing method of bed side panel crossbeam | Effectively heating up by 580 degrees and naturally cooling down, then using a five sided machining center for precision milling of the machining surface, and then using a side milling head for drilling and tapping to synthesize once, with a machining accuracy of 5 threads |

4 | Rail rack | After the installation of the guide rail rack is completed, use a slider to push the dial indicator and adjust it to an accuracy of less than 5 threads |

5 | Transmission assembly | Taiwan original TBI screw, with a diameter of 25 leading to 10mm, Taiwan 30 square rail |

6 | Complete rack | Crescent high precision helical tooth |

7 | Z Shaft assembly | The Z-axis adopts a holding brake motor, which will not slide or fall due to power failure. It adopts Japanese NCK integrated bearing module nuts, which can ensure smooth up and down concentricity. The lead screw is 2510, with fast speed and high accuracy |

8 | Complete machine motor | Maixin 850W servo motor and servo drive |

9 | Complete machine reducer | The XY reducer is made of Zhuo Blue and has a flange diameter of 130. There are three units in total, one for X and two for Y |

10 | Spindle power Tool magazine form | The Italian Oli 9KW automatic tool change spindle has a tool magazine arranged horizontally and vertically under the crossbeam, with a capacity of 12 tool magazines for the tool change spindle to freely adjust and process. |

11 | Frequency converter | Shenzhen Yidian Tong 11KW frequency converter. |

12 | Countertop structure | 7.5KW water circulation vacuum pump, after improving the pipeline, there is no need to increase the vacuum pump. The pump has a large power loss, ensuring that the board does not run out |

13 | Adsorption pump power | 7.5KW water circulation vacuum pump, after improving the pipeline, there is no need to increase the vacuum pump. The pump has a large power loss, ensuring that the board does not run out |

14 | Dust suction method | Each machine head is individually sealed by a cylinder to increase the dust suction flow at each dust suction port |

15 | Vacuum cleaner (optional) | 3.0KW dual bucket vacuum cleaner with a sealed suction port with high flow rate, eliminating the need for a high-power vacuum cleaner |

16 | operating system | Taiwan Jingke Control System |

17 | Knife setting method | High precision magnetic tool setting instrument, with an accuracy of less than 2 threads, and an automatic tool setting system that is convenient to use |

18 | Electrical components of distribution box | Schneider ABB AC contactor 32M7C, and 18M7C model, 60A circuit breaker |

19 | Complete machine cable | Customized high flexible double sheathed shielded mesh square cable with isolated wiring method, the cable will not bend, wrap, or twist inside the drag chain |

20 | positioning system | Five positioning cylinders, two at the front end and three at the side end to ensure a 90 degree right angle, with higher precision in flipping plate processing. The five axis machining center is milled with one tool, and the installation dial gauge has precision. The horizontal and vertical positioning cylinders are within 5 threads |

21 | Double saw blade | Main spindle power 5.5KW, saw blade diameter 200-400mm |

22 | Double pressure roller | Aluminum welded whole board, dedicated double pressure roller for honeycomb board |

23 | chassis | Independent chassis, roller type, can freely move the chassis position |

24 | Overall speed value | The actual cutting speed is 15-30 meters, and the air travel speed is 70 meters per minute |

25 | support software | Haixun, Yunxi, 1010, Yimu, Tongde and other cutting software and cabinet door software |

26 | Oil way | Automatic oil injection pump, each point can independently adjust the amount of oil injected, timing, and other functions |

27 | Table control structure | Automatic switching control table (dual station only) |

28 | safety system | 超程双限位,急停按钮保护,气压不足保护,配电箱开门断电,电 压缺项等安全保护 |

29 | Machine tool standards | International export CE certification, export standards |

Technical Parameter

Serial number | Performance refers to 标 |

Parameters | |

1 |

stroke | X stroke | 1300mm |

Y stroke | Station 1: 3000mm 工 位 2 : 3000mm | ||

Z stroke | 200mm | ||

2 | Platform size |

| 1420*7200mm |

2 | Precision | Precision | ±0.05mm |

Repeatability | ±0.05mm | ||

3 |

structure | Countertop structure | Vacuum adsorption |

X 、Y 、Z structure | X 、Y rack,Z Lead screw | ||

4 |

speed | Maximum empty travel speed | 80000mm/min |

Working speed | 30000mm/min | ||

5 | Spindle | Spindle power Double saw blade | Olly 9KW Main spindle saw blade power 5.5KW |

Spindle speed | 0-24000r/min | ||

6 | Operating mode |

| Maixin servo |

7 | Operating Voltage |

| AC380V/50Hz |

8 | Run command |

| G Code |

9 | operating system |

| Taiwan Jingke System |

10 | net weight |

| 4600Kg |

service

- 设备安装和调试 *设备到达用户后,一铭数控技术工程师当天到达用户现场进行安装、调试培训

*Please prepare the work before the engineer arrives at the site. For example: unloading equipment, equipment site, power supply, computer, plug, voltage regulator, leakage protector, please actively cooperate with the user, and after the equipment debugging is completed, please ask the user to accept it

*The trainee must have certain relevant academic qualifications and knowledge, and the supplier will train the customer in programming, operation, processing and daily maintenance. The trainee must be fixed and study carefully.

*The supplier's technical engineer conducts periodic follow-up visits to customers, and conducts machine operations and product processing with them

Face to face technical communication, users can consult Yiming with any questions at any time through phone and email.

*Pre-sales free use training for customers.

*The trainee must have certain relevant academic qualifications and knowledge, and the supplier will train the customer in programming, operation, processing and daily maintenance. The trainee must be fixed and study carefully.

*Supplier technical engineers visit customers from time to time, and communicate with customers on machine operation and product processing. Users can consult Yiming any questions by telephone or email at any time.

- After-sales service

* During the warranty period, the machine will be repaired free of charge, and the equipment repairs within the warranty period will be clearly marked.

*The warranty period provides customers with two free maintenance.

*General maintenance work is carried out on-site, and the corresponding maintenance time does not exceed 36 hours

*设备整机免费保修壹年

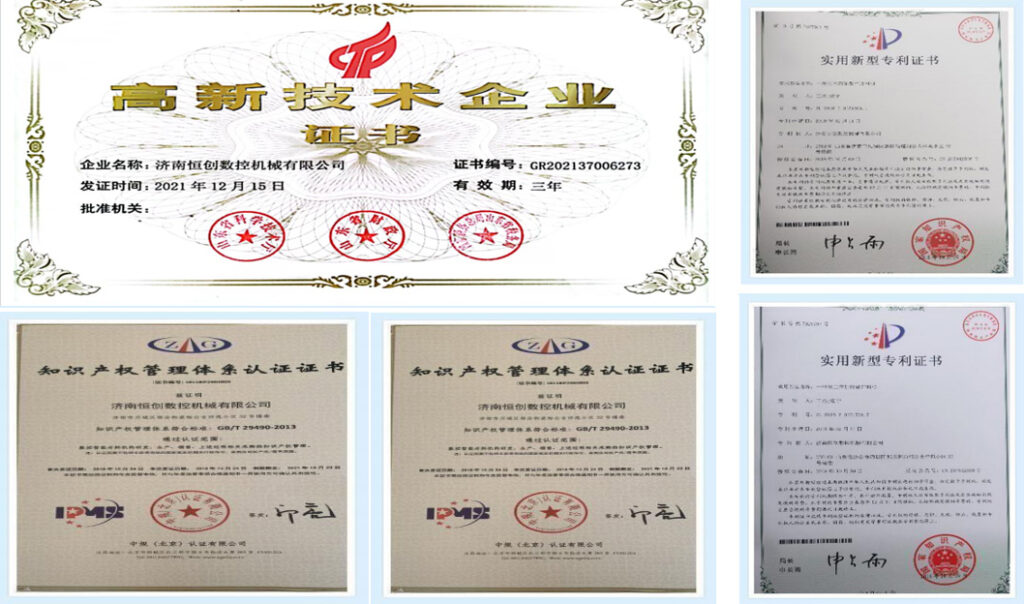

qualification documents

Preparation before equipment placement

1Equipment environmental requirements

Confirm that the equipment is in place at the designated location, and generally recommend a concrete floor;

Confirm the preparation status of workshop power supply, gas source, sockets, etc

The recommended storage temperature for C is generally 0-45 ℃, with a relative humidity of 40% -80%

D No hazardous materials, such as flammable, explosive, highly corrosive gases, etc

2、 For trainees, operators are required to be familiar with simple computer operations, diligent and eager to learn. It is recommended to have two or more people learning at the same time

3、 Equipment installation training

After the A device arrives at the designated location, the user checks the appearance of the device for any damage or bumps. If there are any abnormalities during the transportation process, please contact us as soon as possible and wait for confirmation before receiving the goods. If you sign and receive the goods without authorization, you will be responsible.

After the B engineer arrives at the training site, the user conducts a basic acceptance and begins the training. The engineer will install and debug the machine within 3-5 days for the customer to use, ensuring that the installation is neat and orderly.

C 培训内容包括:设备操作,软件操作,日常维护保养,简单故障排除等。

After the training is completed, the customer inspects and fills out the training form for the trainees based on the actual situation

并对技术工程师做出评价,以便我们做的更好